Increasing agility and competitiveness with digital manufacturing

Products are becoming more and more complex to produce: more demand for customisation, shorter delivery times, tighter inventories, changing production technologies and more.

In today’s world, manufacturers must have a flexible production chain that can easily adapt to new priorities and put technological innovations to use: additive printing, cobotics, MES, digital twins, industrial 5G, etc.

Our Manufacturing solution is built around several concerns and aims to integrate production constraints from the design stage onwards so as to respond quickly to customer expectations.

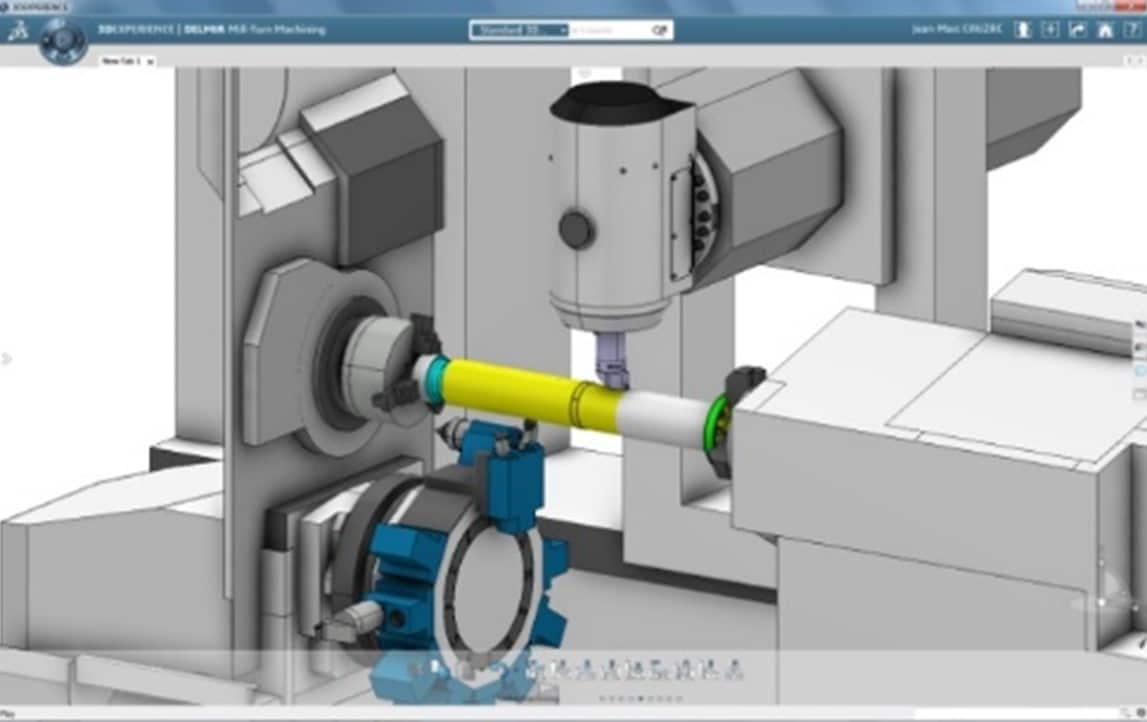

Make communication easier between the design office and production by connecting them to manufacturing process simulation tools like SOLIDWORKS CAM, MBD, PLASTICS, to avoid inconsistencies, tailor machining rules, avoid costly rework and secure toolpaths.

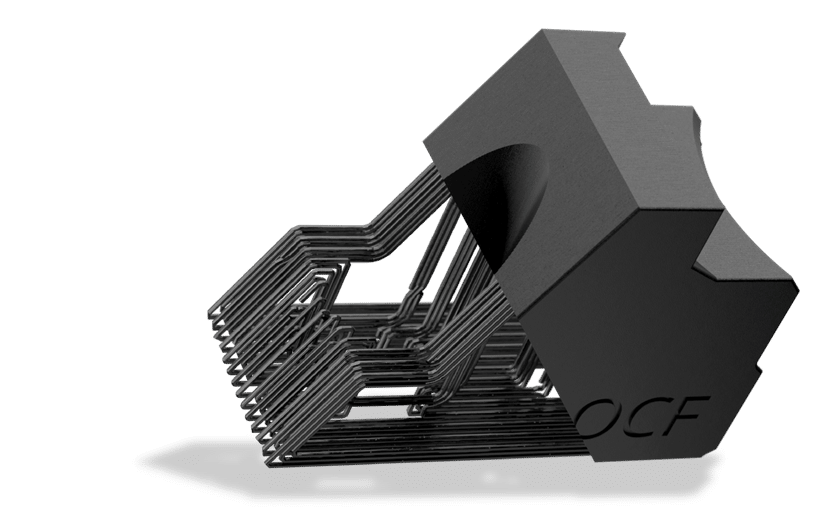

Accelerate your projects with new integrated manufacturing technologies : Deliver fast prototyping and multi-property parts with 3D printing; improve toolpath accuracy and reduce programming time with advanced machining solutions.

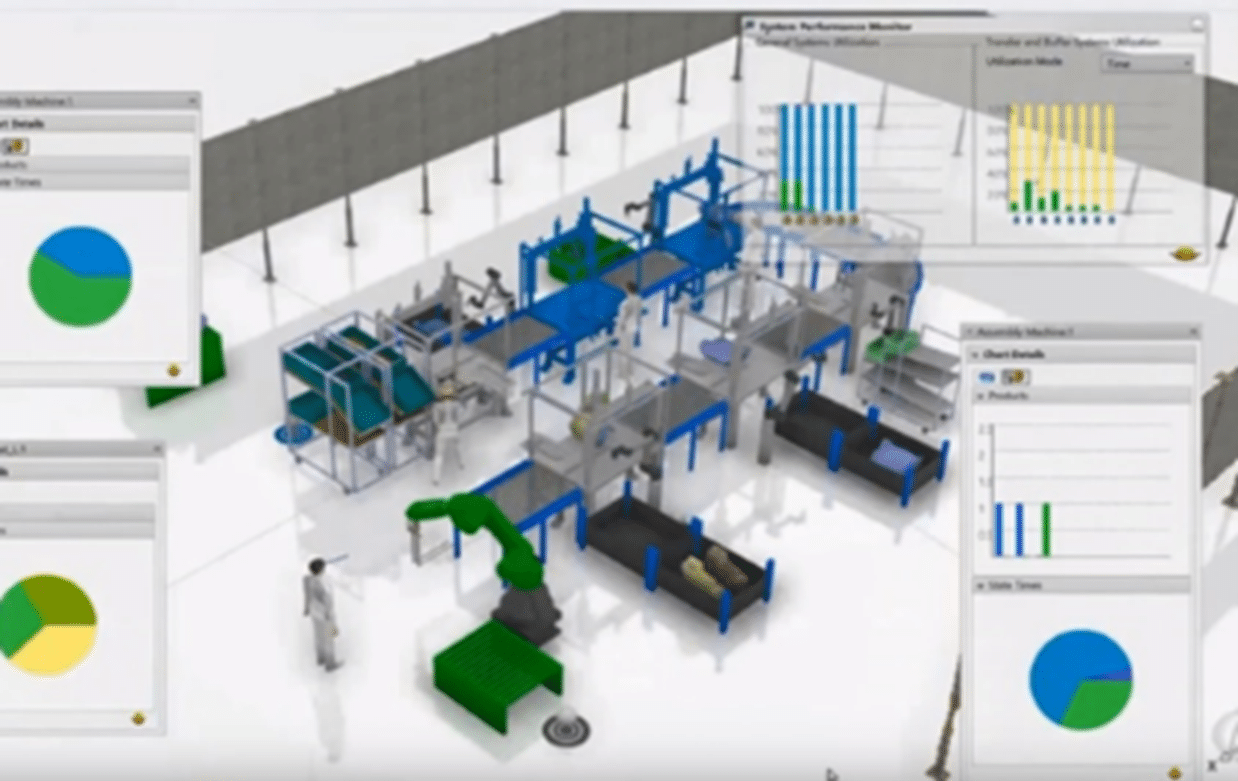

Enhance your operational excellence by making the right production decisions.Test all production, scheduling and planning scenarios on your resources’ digital twin.Deploy effective preventive and predictive maintenance

Integrate your resource constraints and scheduling processes.Enhance your production line flexibility and significantly reduce the administrative planning workload with scheduling and planning solutions like Ortems, Planilog or Productys

Start designing with SW CAM, reduce machine programming time with DELMIA, and simulate material dynamics with SOLIDWORKS PLASTICS for a fast product development cycle.

Using the right 3D printer, HP, Markforged or Formlabs, depending on your requirements for hardness, complexity, customisation of your products.

Test your scenarios on the 3DEXPERIENCE TWIN digital twin at facility level, production line level or equipment level to increase your productivity.

“Depending on the part and the volume, I advise employees to use 3D printing. An example of this was an order for 5,000 small parts, which the printer was able to produce faster and cheaper than plastic injection.”

Cédric Martinez

Project designer

“During the six-year period since we rolled out the DELMIA solution, we’ve been able to transfer two of our high-capacity production lines from France to our new plants in the US and Chile, while improving the productivity of our French plant by 20%. This was all made possible by simply pooling our orders and optimising our production flows.”

Jean Kasapyan

Production Manager

The challenge: In-house manufacture of prototypes

The solution: Markforged and HP 3D printers

Benefits: By integrating additive manufacturing, the design office can reduce discussion time with the mould maker by testing and optimising the part until it is validated and the final mould can be ordered for plastic injection to begin.Aldes gains agility and productivity by customising tooling that adapts to the operators.

The challenge: Meeting the delivery deadlines imposed by the clients

Solution: 3DEXPERIENCE Twin

Benefits: Simulating the new site and the necessary equipment so as to determine the optimal location for repatriating the production of standard parts to France. Developing the digital twin of the factory to test change scenarios in line with priorities.

The challenge: Stepping up production flow to control customer lead times, reduce product loss and breakage on the shop floor, and maximise equipment use.

Solution: DELMIA ORTEMS

Benefits: Customer lead times have been reduced from 10 to 3 working days, as have product shortages in the workshops.A higher degree of control over the operating rate of the machine base requiring less human intervention.

Range DELMIA

Reach operational excellence

Design and optimize your production cycle in a digital twin, your simulated production environment.

Range SOLIDWORKS for CAD

Design in 3D with intuitive and high-performance tools

Design your parts and assemblies with the complete SOLIDWORKS suite to turn your ideas into ground-breaking products.

Range 3DEXPERIENCE

Innovate and share in real time

Access all product lifecycle applications from a single platform to facilitate collaboration between all those involved in design, simulation, manufacturing, maintenance...

Visiativ Transformation Diagnostic

Maximize the performance of your company

Global audit of your digital maturity and prioritized roadmap for growth

PLM 3DEXPERIENCE Consulting

Benefit from adapted support during the deployment of your 3DEXPERIENCE project

Define the PLM support that suits you: a packaged service or a customized offer according to the challenges of your development cycle.

Visiativ PLM Diagnostic

Optimizing your industrial processes

Supporting your PLM deployment to achieve together the goals you have set for yourself

Industry has been Visiativ’s core development concern for the past 35 years.

We support you on a daily basis in transforming your industrial processes and tools by providing you with a club dedicated to feedback from the Industry of the Future is an obvious choice! Join the community and share your experience with the challenges of Industry 4.0.

Manufacturing business solution is a business solution from Visiativ Innovation Engine.

Our cloud innovation platform is a unique and innovative approach that offers a continuum of local services for the digital, social and environmental transformations of SMEs and SMBs: services and solutions to plan, implement and manage your transformations, to enhance your competitiveness and your company's performance.

For over 35 years, Visiativ has been helping SMEs to accelerate their innovation, improve their competitive edge and meet their sustainable development commitments. We are a trusted advisor, with a real ability to deploy solutions, in a collaborative economy of shared experience.